© 2019 Burt Forest Products

Grades of Domestic (North American) Hardwood Plywood.

Here is a simple but practical explanation of hardwood plywood grading:

Plywood grades are (best to worst) A, B, C and D for face or front face. The back grades are (best to worst) 1, 2, 3, and 4. Plywood grading standards are published by the Hardwood Plywood & Veneer Association. (see below)

Plywood grades of A1, A2, B1, B2 are a good two sided product and would be used where both sides are going to be seen. The back side (number grade) does have a few more blemishes than the front.

A3, B3, C3 are for plywood that will be seen from one side, but the back side must be clean, although there may be some stain or discoloration on the back, spliced veneer, and so on. One might use this material for the sides of a dresser (who looks inside?), for drawer sides, and shelving.

A4, B4, C4 are a one-side-good product. The back may have open knots, filled knots, bad veneer joints or seams. This material will would work well for drawer bottoms, and similar.

From Professor Gene Wengert, Sawing and Drying Forum technical advisor

Here is a description of the core choices that are available:

Core Types: Decorative hardwood plywood cores are mostly veneer (66 percent of the panels sold in North America), but may also be MDF (16 percent), particleboard (13 percent), or agrifiber and other materials.

|

|

Veneer core is made from multiple plies of veneer peeled from quality logs with limited aesthetic characteristics, and glued together with the grain direction alternating at right angles. Compared to MDF (medium density fiberboard) and particleboard, its advantages include higher strength, lighter weight (typically 70 pounds at ¾-inch thick), and excellent screw-holding properties. Disadvantages include potential variation in panel thickness; core textures may telegraph through the surface layer; and the edges must be covered.

|

|

|

MDF core are wood chips steamed and refined to fiber bundles, bonded, formed into a mat, pressed and then sanded to a desired thickness. Advantages include a smooth surface, uniform thickness, and reasonable screw-holding ability. Disadvantages would be that it's heavy (100 pounds at ¾-inch thick), not as strong as veneer core, and the perception that it is not real wood.

|

|

|

Particleboard Particleboard cores are made from wood chips ground into small particles, bonded, mat formed, pressed and sanded to a desired thickness. Advantages include a smooth, uniform thickness and reasonable screw-holding ability. Cons would be that it's heavy (100 pounds for ¾-inch panel), not as strong as veneer core or MDF, and again, the perception that it is not real wood

|

|

|

Combination core plywood consists of two types of construction. The first has a center veneer layered with a crossband veneer on both sides and then followed by a layer of MDF, particleboard or hardboard, plus the face and back veneers. The second type of construction has a wafer-board center with a veneer crossband on both sides, plus the face and back veneers. Combination core offers consistent flatness and good screw-hold ability in a lighter weight than MDF or particleboard.

|

|

|

Lumber core plywood is constructed from strips of solid lumber. Veneer is attached once the core has been surfaced. Lumber core plywood has good bounce-back, which makes it a good choice for constructing long or wide shelves in cabinets and closets. A more expensive plywood, it is diminishing in popularity.

|

Decorative hardwood plywood—the responsible way to specify rare and precious species.

By Georgy Olivieri, LEED AP and Karl Schrumpf Originally published in Interiors & Sources

By Georgy Olivieri, LEED AP and Karl Schrumpf Originally published in Interiors & Sources

Face, Back and Inner Ply Grades of Veneer, as Defined by the ANSI/HPVA (Hardwood Plywood & Veneer Association) HP-1-2004 Standard

The "face" is the better side of any plywood panel in which the outer plies are of different veneer grades. If both sides are the same grade veneer, they're both face surfaces. The side opposite the face of a panel, or the poorer side of a panel in any grade of plywood, is the "back." Back veneers have a separate grading system, as do veneers used in the core of the panel.

There are six face grades in the product standard:

|

·

|

AA is the highest grade, with very limited allowance for size and presence of natural characteristics

|

|

·

|

A is the next highest grade, allowing slightly more and larger natural characteristics

|

|

·

|

B, C, D, and E follow, each allowing for progressively more and larger natural characteristics

|

There are four back grades, which naturally allow for more imperfections like sapwood, discoloration and stains, mineral streaks, burls, and larger knots:

|

·

|

1 is the highest back grade, which allows no combined knotholes and repaired knots

|

|

·

|

2 and 3 are mid-range back grades, which limit the number of combined knotholes and repaired knots

|

|

·

|

4 is the equivalent of a veneer reject grade, allowing an unlimited number of combined knotholes and repaired knots

|

There are four inner ply grades intended for classification of inner ply veneers, with limitations on openings and splits:

|

·

|

J and K are the higher grades and are permitted under the face of B-grade and higher panels

|

|

·

|

L is a lower grade permitted under C-grade and lower faces

|

|

·

|

M is suitable for only inner ply applications

|

Two-sided panels may be specified.

|

·

|

A panel may be specified with a face grade on both sides (e.g., A-B PS cherry will have an "A" grade face on one side and a "B" grade face [technically a back] on the other).

|

|

·

|

A panel may also be specified with a face grade from one species on one side and a face grade from a

|

Here is the industry standard guidelines:

Definitions - Domestic Hardwood Plywood

Our sales staff is here to answer your questions!

Contact us by phone at 800-322-2878 or by e-mail at info@burtforest.com.

Contact us by phone at 800-322-2878 or by e-mail at info@burtforest.com.

Columbia Forest Products

The way sheets of veneer are then spliced back together (or left whole) further determines the look of the finished panel.

Veneer Splices:

Decorative hardwood plywood—the responsible way to specify rare and precious species.

By Georgy Olivieri, LEED AP and Karl Schrumpf Originally published in Interiors & Sources

By Georgy Olivieri, LEED AP and Karl Schrumpf Originally published in Interiors & Sources

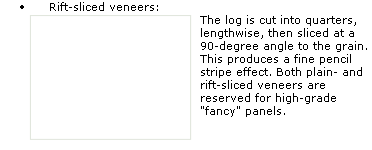

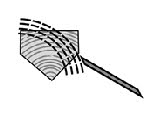

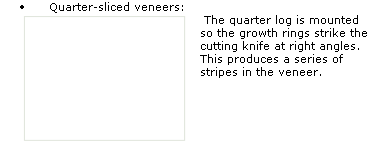

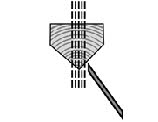

There are many types of veneer cuts, each yielding a different appearance.

Veneer Cuts:

Veneer Cuts and Splices

Hardwood Plywood Grading